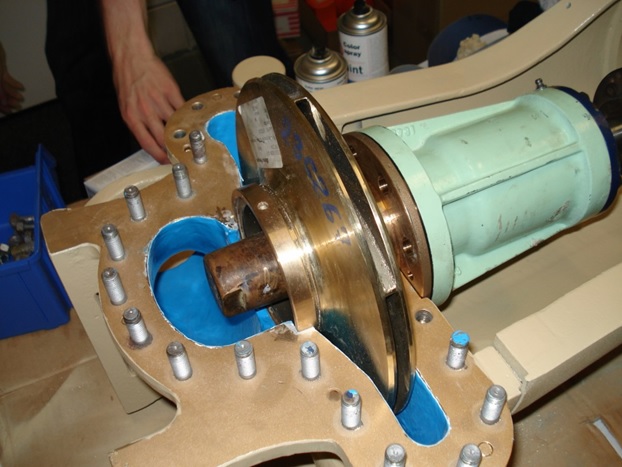

Mechanical Seal Repair

ALTUS pioneered mechanical seal repair and reconditioning in Philippine industries, allowing companies to save up to 60% in costs.

Our services cover all types and brands (standard, special-design, and OEM seals). This includes replacement of damaged components, insertion and lapping of seal faces, and leak testing. Repair services are in accordance with the manufacturer's original dimensions and tolerances.